We study optical microstructure fabrication using azopolymer films and laser lithography. Films are spin-coated in our thin-film lab and characterized in our atomic force microscope (AFM) facilities. We focus on 1-step fabrication using spatial light modulators as well as structure replication using nanoimprint lithography.

Our research is supported by the National Science Foundation Division of Materials Research (award 1919557) and Division of Electrical, Communications, and Cyber Systems (award 2024118).

Research positions are available in my lab for TCNJ students in the Schools of Science and Engineering and for visiting research students from Berlin Institute of Technology (BHT) through the ELBA program. Read about our ongoing projects below, and see the latest images from our newest projects in Dot-Matrix Holography, Color Control, and Image Multiplexing.

Projects

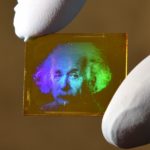

- Dot-matrix holography– Images are written as a matrix of surface-relief microholograms. We are exploring multiplexing techniques for structured color and the storage of multiple independent images to simulate motion. More information and images can be found here.

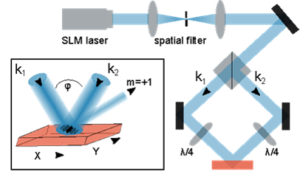

- Surface grating amplification and reconfiguration- Azobenzene-polymer films respond to optical polarization, and can be used as optically reconfigurable surfaces. We exploit this to explore how sinusoidal surface gratings can be reconfigured and even set into motion.

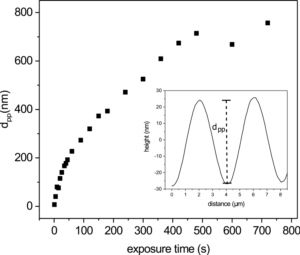

- Supramolecular azopolymer materials– We collaborate with the TCNJ chemistry department on the development of supramolecular azobenzene-polymer films. Supramolecular materials rely on hydrogen bonding, resulting in a versatile and easily materials platform capable of surface relief gratings > 800 nm.

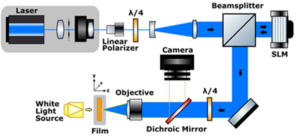

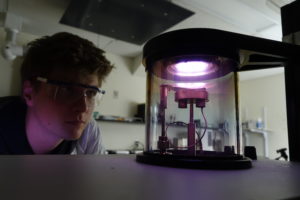

- Spatial Light Modulator (SLM) for 1-step fabrication– We use SLMs to project structured polarization fields for the programmable fabrication of surface microstructures. Sinusoidal, circular, and chirped gratings can be generated with single optical exposures.

Capabilities

- Laser interference lithography– We use 488 nm diode-pumped solid state (DPSS) lasers for laser interference lithography. We use Python to automate all aspects of exposure and film translation.

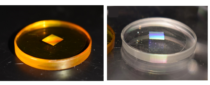

- Structure replication– Our optical microstructures can be replicated using nanoimprint lithography. We utilize PDMS-molding to fabricate high fidelity replicas of structures.

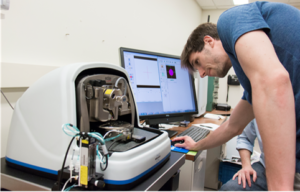

- AFM– Optical microstructures are characterized primarily by atomic force microscopy (AFM). The TCNJ physics department houses a research-grade Bruker Dimension Edge AFM, which can measure film surface topography variations with sub-nanometer resolution.

- Thin-film fabrication– We have a dedicated laboratory for thin-film fabrication. Solutions for photoresist and azobenzene-polymer films are prepared and deposited on a variety of substrates using spin-coating. The lab contains a sputter coater for the deposition of metallic overcoats and for fabrication of reflective substrates.